Pre-Starts with Immobilisation

Teletrack’s PROSTART® Pre-Start system is a game-changer for job site safety. By default, all Teletrack-enabled assets are immobilised, ensuring that machinery remains inoperative until a comprehensive, image-based safety questionnaire is completed satisfactorily. Operators scan a unique QR code on the asset to access a customised pre-start checklist via Teletrack’s web-app. This checklist ensures that critical safety checks are performed, covering aspects like fluids, filters, and overall equipment condition. Only upon successful completion is the asset mobilised, reducing the risk of accidents due to faulty or unsafe equipment. If a pre-start fails, the asset remains locked, and managers are immediately alerted, ensuring that safety is never compromised.

Driver-ID

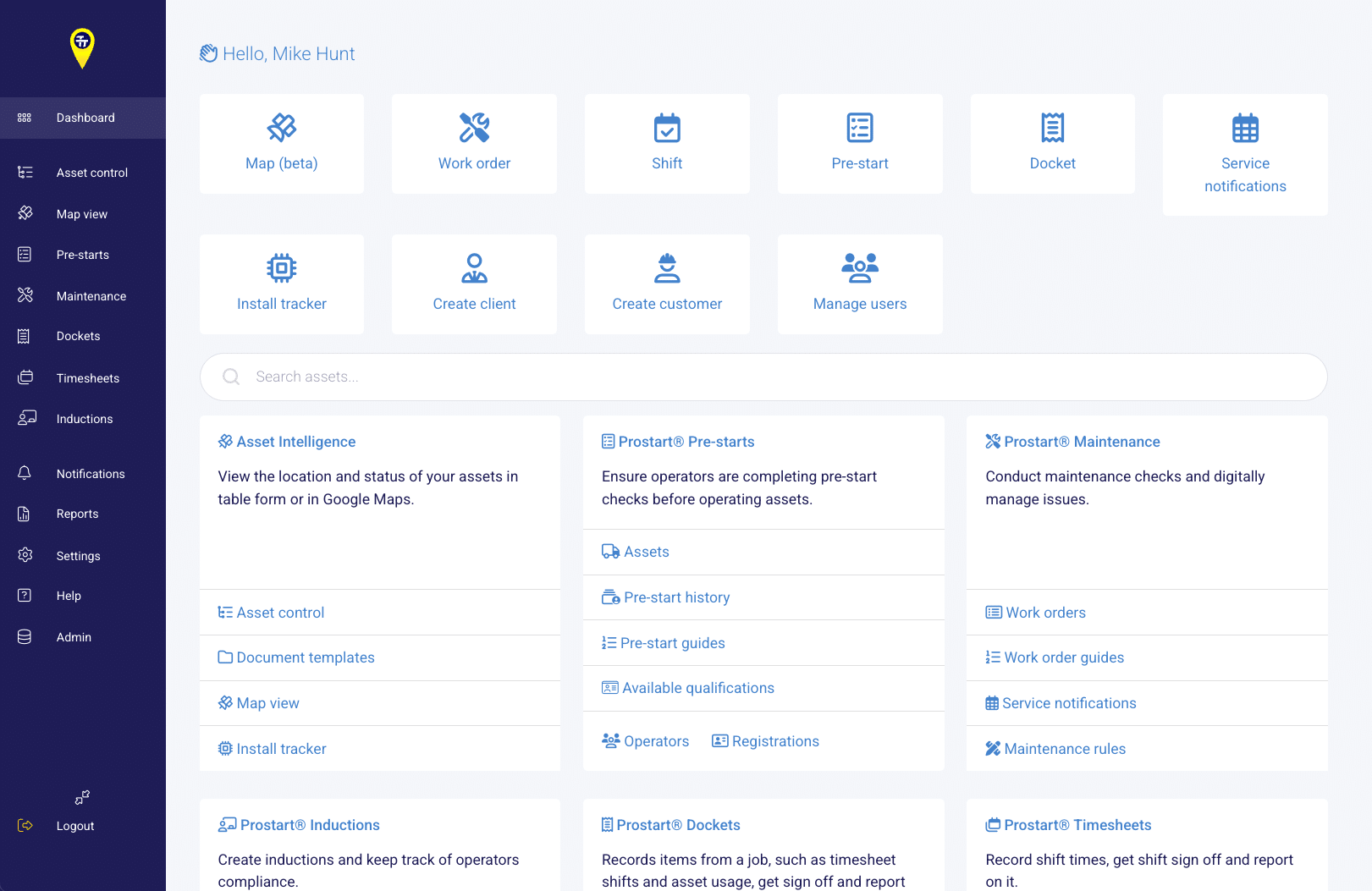

Operator accountability is critical to maintaining a safe job site. Teletrack’s Driver-ID system ensures that only authorised and qualified personnel can operate machinery. Each operator is assigned a unique login, accessible via RFID, iButtons, or keypads, eliminating the need for shareable access codes that could compromise security. By scanning the QR code or using their Driver-ID, operators access the pre-start questionnaire, and their activity is logged for transparency. Managers can remotely verify qualifications, control access based on certifications, and monitor usage logs through the Teletrack dashboard. This system not only prevents unauthorised use but also tracks operator behaviour, such as harsh acceleration or braking, further enhancing safety and accountability on-site.

Generate Work Orders from Pre-Starts Where Issues Are Flagged

Teletrack’s integration of pre-start checks with its Maintenance Module streamlines issue resolution. When an operator flags a problem during a pre-start—such as equipment damage or faults—the system can automatically generate a work order. This feature, highlighted on Teletrack’s website, ensures that issues are addressed promptly, preventing minor problems from escalating into costly repairs or safety hazards. Managers receive real-time alerts and can assign service technicians to resolve issues, with all data logged in a digital maintenance record. This proactive approach minimises downtime and ensures that only fully operational assets are used, reinforcing job site safety and compliance.

Routine Maintenance from Automatic Service Schedules

Effective maintenance is crucial for safe machinery operation, and Teletrack’s Maintenance Module excels in this area. As detailed on their asset maintenance page, the system automates customised work orders and service reminders based on asset usage hours and odometers. Service technicians can log checks, inspections, parts, and faults into a digital logbook, accessible via QR code, ensuring a comprehensive maintenance history. The module also supports 24/7 remote alerts for critical faults, enabling swift action to prevent accidents. By integrating maintenance schedules with real-time telematics data, such as engine performance and fuel efficiency, Teletrack helps businesses optimise uptime, reduce repair costs, and ensure that assets are always in safe working condition.

On-Site Inductions

Teletrack’s system simplifies operator inductions, ensuring that all personnel are trained and compliant before operating machinery. New operators complete a digital registration form via QR code, entering personal details, licenses, and qualifications. Supervisors verify this information remotely and approve access, after which operators receive unique login details via SMS or email. The system also supports site-specific induction videos, familiarising operators with safety protocols and asset operation. Teletrack tracks compliance, sends renewal notifications, and maintains records of completed inductions, ensuring that only competent operators access assets. This process enhances safety by reducing the risk of unqualified operation.

By combining pre-starts with immobilisation, Driver-ID, automated work orders, routine maintenance, and robust induction processes, Teletrack’s PROSTART® system delivers a comprehensive solution for job site safety. This Australian-made platform empowers businesses to protect their workforce, comply with regulations, and optimise asset performance, making it an indispensable partner for the construction industry.